THE BACKSTORY

Circa 1700

The year was 1700. Self-sufficiency reigned in this agriculture-based society. If a blanket or quilt was needed, you produced it. If chicken or beef was for dinner, you butchered and prepared the meat.

Local craftsmen – blacksmiths, woodworkers, and gunsmiths – offered custom goods to the local populace. Should you need a shoe mended, a visit to the local cobbler was in order. When your horse needed shoeing, to the blacksmith you went. These producers of one-of-a-kind custom goods founded early manufacturing in North America.

Despite high quality production, there was one problem: early craftsmen only produced small quantities of goods, limiting their overall impact to local economies.

1700s

300 revolutions around the sun later, and North American manufacturing found itself among the largest and most powerful in the world – a reality that largely underpins our countries’ economic strength and stability.

How did North Americans go from small, local craftsmen producing custom goods to being one of the largest and most prominent producers in the world?

Factories, machines, the light bulb, assembly lines, giants of industry and North American craftsmen – these people and inventions propelled North American manufacturing to become the largest in the world by the early 1900s, eventually advancing us to one of the most globally powerful countries.

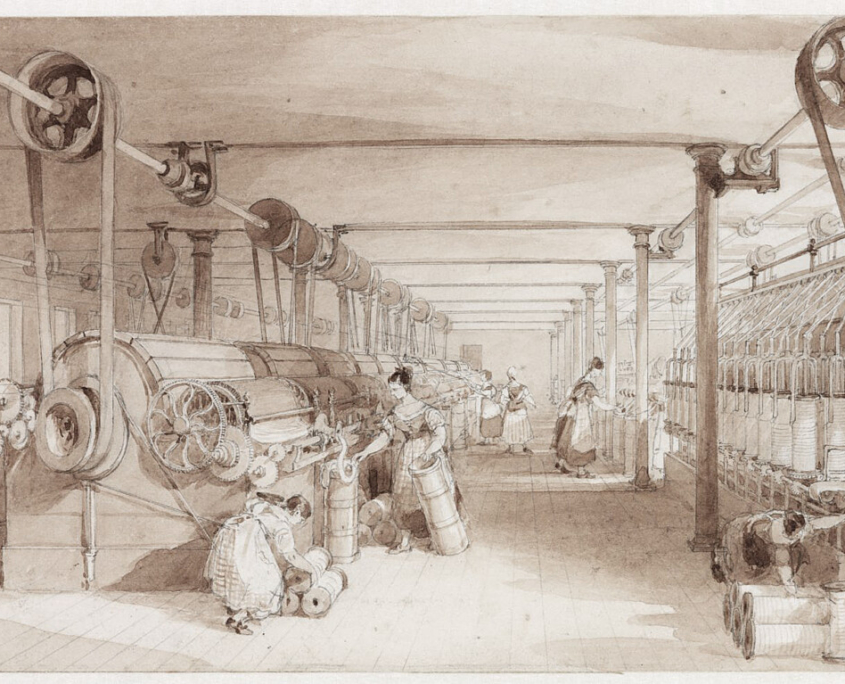

1790

Samuel Slater, referred to as the Father of the Industrial Revolution, built North America’s first factory in Rhode Island. Revolutionizing the textile industry, this plant leveraged water to power its cotton-spinning mill. Originally powered by workers walking on a treadmill, this innovative use of water as an energy source led to significantly increased output.

It was this invention – the factory – that would replace the local craftsmen’s workshop, revolutionizing the workplace into a collective group seamlessly producing goods.

1790

1798

1798

Eli Whitney’s Interchangeable Parts

Eli Whitney, under governmental contract, developed the concept of interchangeable parts. This concept transitioned manufacturing from expensive and time-consuming hand-made products to mass produced, nearly identical goods. Interchangeable parts would lay the groundwork for large-scale machine use in manufacturing.

It was this invention, interchangeable parts – that would become the catalyst to North America’s ability to produce vast volumes of goods in the coming centuries.

1830

The Industrial Revolution

Small groups of local craftsmen producing hand-made products out of their local workshops in the early 1700s grew to over 500,000 strong. With the use of coal and water to power machines and large factories, North America saw substantial increases in its volume of manufactured goods. By the start of the 21st century, North America became a prominent world power.

1830

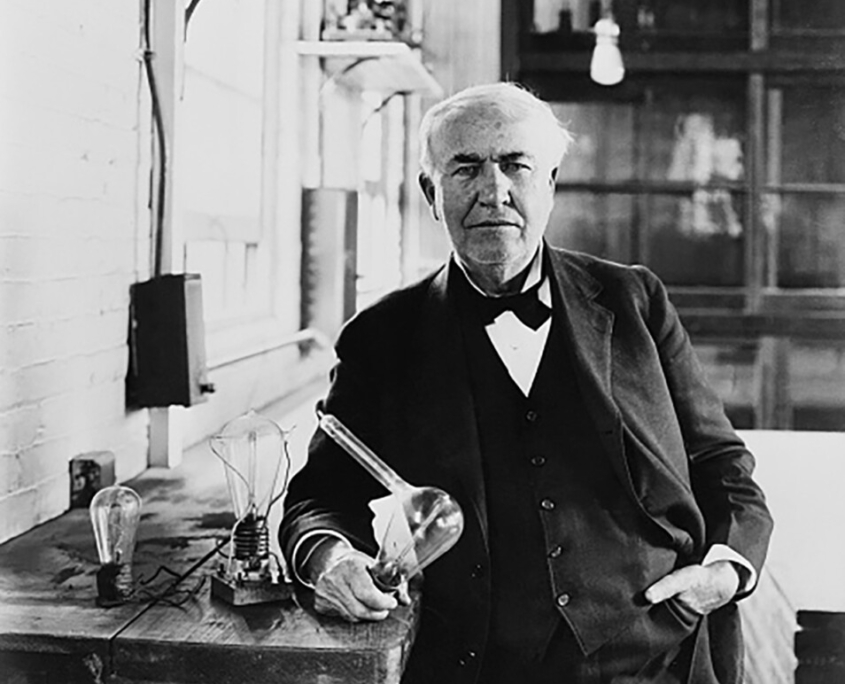

1879

1879

Edison – Father of the Night Shift

Thomas Edison’s invention of the carbonized filament lightbulb – burning for 14 hours straight – had one of the more influential impacts on society, from powering streetlights to department stores. What history overlooks however, is the change that Edison’s light bulb brought to North American manufacturing. Now that workers could see in the dark, factories could run 24 hours a day: the night shift was born.

1900

Birth of Giants

Ford, General Motors, Carnegie Steel, General Electric, Studebaker, Hershey’s Chocolate, Firestone, American Bath Group under the Wm. R. Bootz Manufacturing brand- these industry giants, among others, were born at the turn of the century.

These giants and their millions of craftsmen would go on to advance the entirety of North America and fortify its position as one of the most powerful countries in the world.

1900s

1913

1913

Ford Invents the Assembly Line

By 1913, Henry Ford had broken down the production of the Model T into 84 distinct steps, and each craftsman was trained on just one of these steps along a moving line which brought the work to the craftsmen. Using\ Eli Whitney’s concept of interchangeable parts and the conveyor belt systems he has seen used in grain mills, Henry Ford invented the modern. assembly line.

The concept of the assembly line

- bringing work to the craftsmen

- led to significantly increased output over the next century.

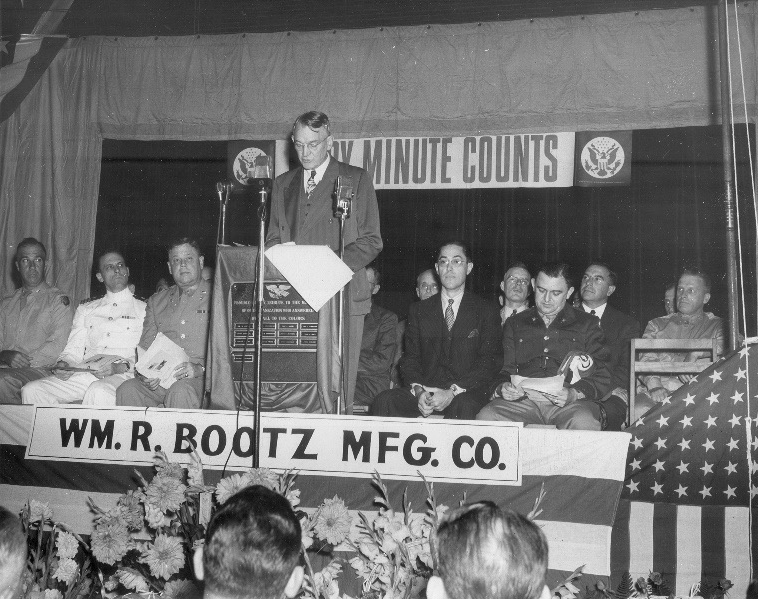

1941

WWII – Doubling of North American Manufacturing

Shortly following Pearl Harbor, America mobilized for war. Leading the charge – North America’s massive manufacturing industry.

Chrysler made fuselages. Wm. R. Bootz Manufacturing made practice bombs and portable cooking equipment. General Motors made airplane engines, guns, trucks and tanks. Packard made Rolls-Royce engines for the British air force. The Ford Motor Company performed something of a miracle, producing a B-24 Liberator every 63 minutes.

By the end of the war, 12 million North American men and women craftsmen were producing more than half of all industrial production in the world.

1941

1942

1942

Giants of Industry Receive “E” Award

Ford, Oldsmobile, General Electric, General Motors, General Mills, Studebaker, Firestone, Hershey’s, Goodyear, Otis Elevator Co., Boeing Aircraft Co., Carnegie Steel Corporation, Wm. R. Bootz Manufacturing – these giants of industry were among the top 5% of companies that received the prestigious Army-Navy “E” award out of 85,000 manufacturers. Awarded to facilities that were particularly outstanding in production for the War and Navy Departments, these noteworthy giants took their place in history.

Wm. R. Bootz Manufacturing stood amongst the best of the giants of industry, earning 6 “E” awards– outnumbering almost all other wartime producers.

Inventing and expanding into the 21st century, these giants of industry and their craftsmen stood the test of time, shaping North America as we know it today. American Bath Group is proud to stand amongst these giants.

The Cornerstone of Our Nations’ Strength

From a handful of local craftsmen in 1700 to 16 million strong today, it is craftsmen – those who produce, sell, and support North American manufacturing – that stand at the cornerstone of our countries’ strength and power.

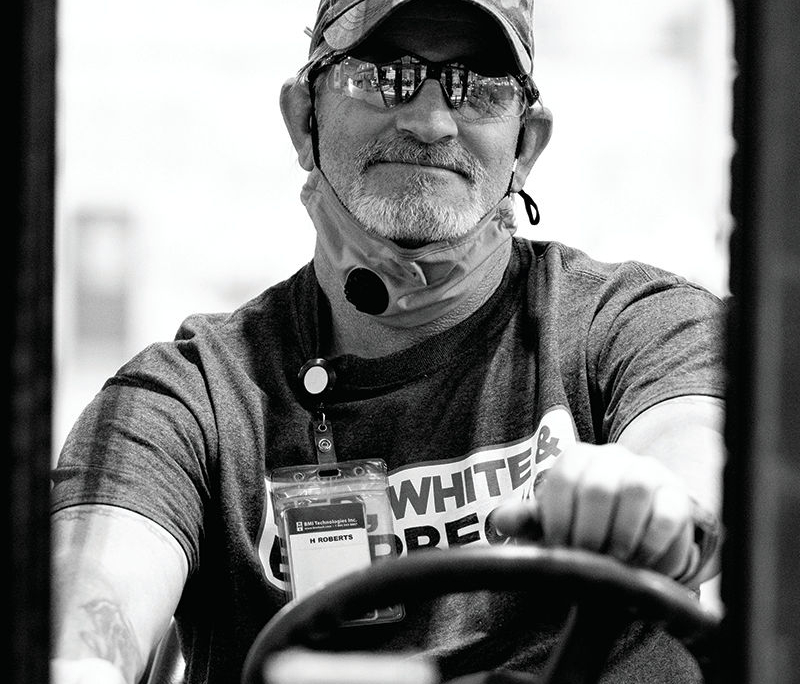

At the American Bath Group, it is our 5,000 craftsmen – the producers, the sellers, the customer-facing, marketing, product developers, dispatchers, drivers, technical support, procurement, warehousers, assemblers, fork-lift operators….It is YOU!